Partners

Give us an idea, and we will return an intelligent factory.

The company has always focused on the research and development, manufacturing and sales of intelligent equipment for special-shaped pipe forming and processing.

Industry Cases

Give me an Ideal, and we will give you an intelligent factory.

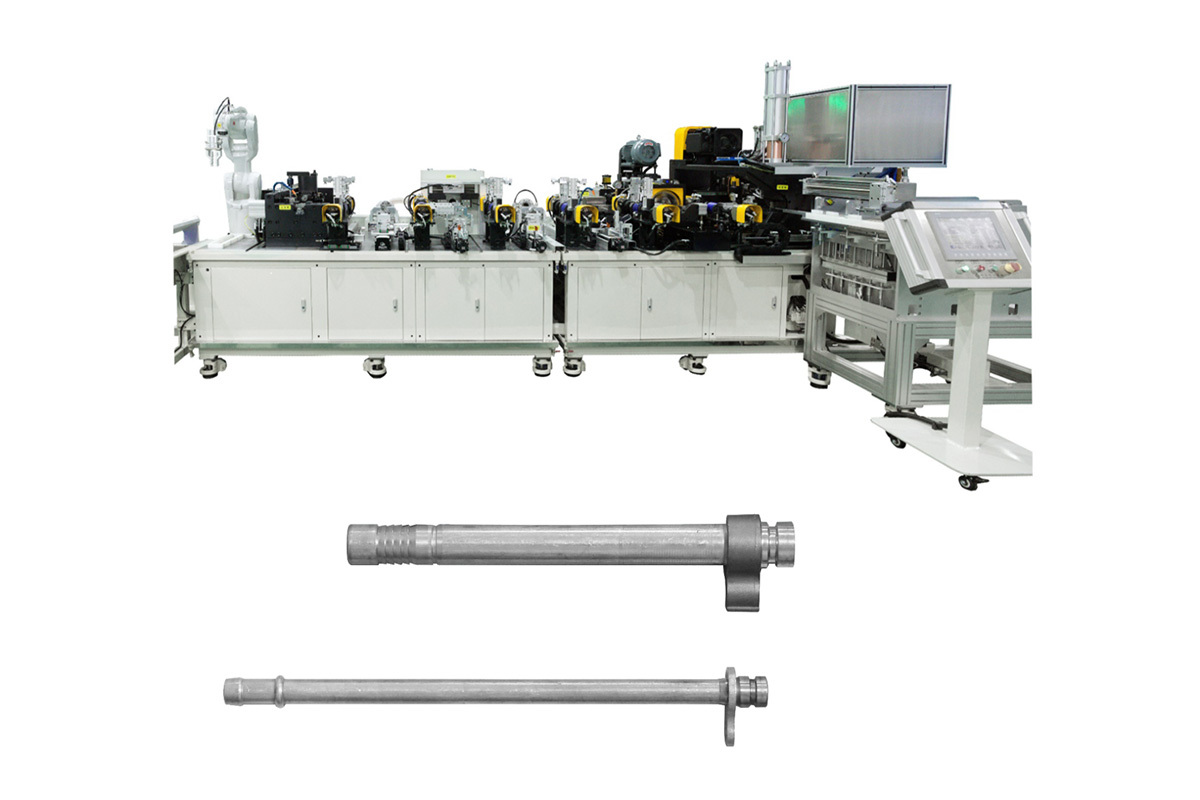

Automatic Production line for High-Low Pressure Pipeline of NEV

|

Processing OD |

∅9.53-∅19.05mm |

|

Processing length |

120-600mm |

|

Overall efficiency |

15s/pcs |

|

Max oil pressure |

14.0MPa |

|

Max stamping force |

12T |

Fully automatic processing, detect material length on loader→ reducing →grooving → oil cleaning → turn around adding flange →hole punching →oil cleaning → laser coding → code scanning → robotic unloading and stack fittings into washing box

Automatic End forming Production line for Automotive A/C Pipeline

|

Material |

Aluminum |

|

Processing OD |

φ8-φ19.05mm |

|

Wall thickness |

1-2.0mm |

|

Processing length |

140-420 mm |

|

Overall efficiency |

13s/pcs |

|

Min stamping force |

12T |

Fully automatic processing, detect material length on loader→ end forming + adding flange →grooving → chamfering → oil cleaning → detection → robotic unloading and stack fittings into washing box

Automotive Liquid System Pipeline

|

Processing OD AL |

φ5-22mm |

|

Stainless steel |

Φ5-22mm |

|

Carbon steel |

Φ5-25mm |

|

Processing length |

60-700 mm |

|

Overall efficiency |

14s/pcs |

|

Min stamping force |

12T |

Fully automatic processing, end forming + oil cleaning → detection → robotic unloading and stack fittings into washing box

Automatic Production line for High-Low Pressure Pipeline of NEV

|

Material |

Stainless steel |

|

Processing OD |

∅6-20mm |

|

Thickness |

0.5-2mm |

|

Overall efficiency |

30s/ two ends forming |

|

Processing length |

100-300mm |

|

Turn on method |

Face scanning |

Fully automatic processing, detect material length on loader→ end forming →turn around → adding flange end forming →grooving → oil cleaning for both ends→ detection for both two ends → robotic unloading and stack fittings into washing box